Free Path Cantilever Racking

Home » Racking Product Range » Cantilever Racking » Free-Path Cantilever Racking

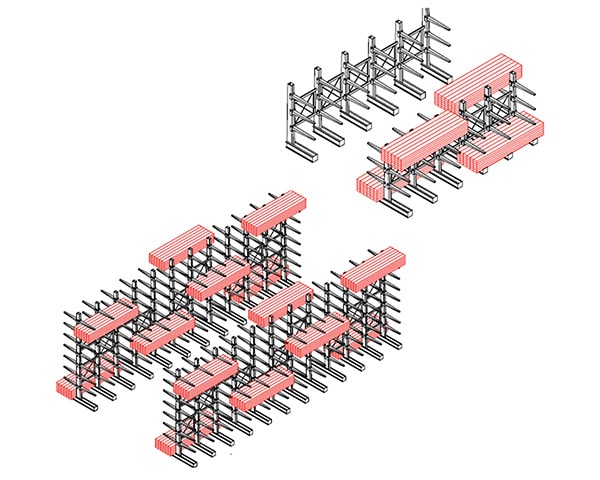

Free Path Cantilever Racking in principal is similar to Conventional Cantilever Racking and is also utilised for storing long lengths of products.

What is Free Path Cantilever Racking?

Free-Path Cantilever Racking consists of rows of racking adjacent to each other separated by an aisle that enables handling equipment to travel the length of the aisle without any guidance system. The full range is manufactured in the UK at our purpose-built factory in Cannock, Staffordshire.

A key factor when operating a Free-Path system is to ensure that there is adequate clearance between the truck and the racks to allow safe and effective loading and unloading of the racks.

Stakapal’s Cantilever Racks are designed to the SEMA Code of Practice for the design of Static Cantilever Racking and/or FEM 10-2-09 and/or BS5950 Part 5 and/or BS EN 1993 -1-3 (Eurocode 3).

Looking To Expand Your Racking?

If you are looking to expand your racking system, Free Path Cantilever Racking offers a flexible solution, whether you are extending an existing setup or starting from scratch. Consult with Stakapal – an approved, reputable supplier and manufacturer of Racking.

What are the features & benefits of Free Path Cantilever Racking system?

- 100% accessibility to individual packs

- Less distance for truck to travel

- Can be used with side loading type trucks, conventional forklift trucks or multi directional reach trucks

- Easily installed or re-positioned

At Stakapal, our in-house teams provide customised, efficient, and innovative storage solutions, whilst ensuring that the racking we manufacture and install maintains its structural integrity over time with regular maintenance, with the guarantee that our racking upholds the strong name of Stakapal.

Our expertise, supported by SEMA certifications, enhances operational efficiency and customer satisfaction.

Racking Variations We Offer

- Single-sided or Double-sided variations

- Top quality durable powder coated finish for internal applications

- Hot dipped Galvanised finish for external applications

- Canopy for External Storage

- Heavy Duty Arms in standard or bespoke lengths

Stakapal are full members of SEMA (Storage Equipment Manufacturers Association), with our installation and inspection teams fully SARI (SEMA Approved Rack Inspector), and SEIRS (Storage Equipment Installers Registration Scheme) registered.

Read some of our Cantilever Racking-related posts

Stakapal takes the racking crown

Industrial Racking At Crown Crown Products is an established kitchen and bedroom manufacturer based in Kent. Stakapal has supplied Crown

Maximising Timber Merchants’ Efficiency

Timber merchants play a crucial role in the construction industry, providing essential materials for various projects. However, managing and storing

The Role of Cantilever Racking in Sustainable Warehouse Practices

Sustainability is becoming a crucial consideration in warehouse management, and cantilever racking systems play a significant role in this shift.

Cantilever Racking Systems FAQs

Cantilever racking is designed to store long, bulky items like pipes, timber, and steel bars. It features arms extending from a central column, allowing easy front access for loading and unloading.

Common types of cantilever racking include: conventional racking, free path racking, and guided aisle racking.

It offers easy access, flexibility, and is ideal for items of varying lengths. It can handle heavy loads and is suitable for both indoor and outdoor storage.

Yes, Stakapal’s hot-dipped Galvanised Cantilever Racking for external applications can also be supplied with a canopy roof for additional protection from the elements. Traditionally utilised by Timber and Builders merchants who have a large requirement for storing Carcassing Timber, a canopy roof is frequently requested as part of the installation in yard areas. We work with the customer to find the most cost-effective solution.

Typically made from steel for strength and durability, and it can be galvanised for corrosion resistance, especially for outdoor use.

Our tapered arms are available in a wide range of lengths from 600mm up to 2100mm, depending upon bespoke requirements. Our most common arm lengths are 1220mm and 2100mm which are widely used in the Timber and Panel Products industries. Arm loadings are available from between 500kgs to 2000kgs.