Guided Aisle Cantilever Racking

Home » Racking Product Range » Cantilever Racking » Guided Aisle Cantilever Racking

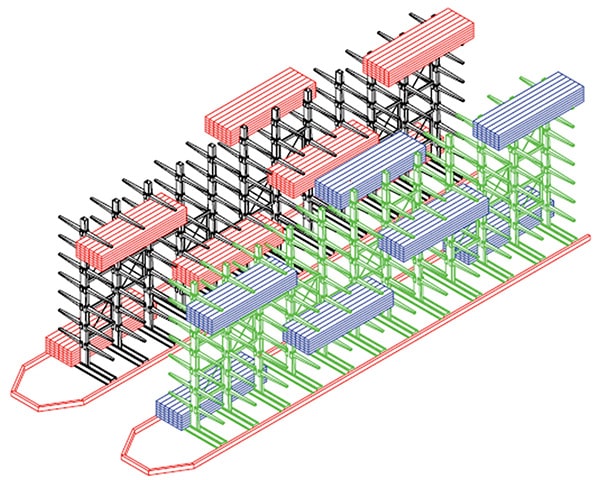

Guided Aisle Cantilever Racks consists of the same basic components as Conventional and Free Path racking systems.

What is Guided Aisle Cantilever Racking?

Guided Aisle Cantilever Racking consists of the same basic components as Conventional and Free Path systems, but with the runs positioned closer together to eliminate the waste of space of a wide aisle. The full range is manufactured in the UK at our purpose-built factory in Cannock, Staffordshire.

Long load products can be stored to a far greater height to ensure cubic space is utilised to the full.

Products are accessed using specialist trucks which are guided by guide-rail systems to avoid damage to the rack structure.

Guided Aisle Cantilever Racks by Stakapal are designed to the SEMA Code of Practice for the design of Static Cantilever Racking and/or FEM 10-2-09 and/or BS5950 Part 5 and/or BS EN 1993 -1-3 (Eurocode 3).

Looking To Expand Your Racking?

If you are looking to expand your racking system, Guided Aisle Cantilever Racking offers a flexible solution, whether you are extending an existing setup or starting from scratch. Consult with Stakapal – an approved and reputable supplier of Heavy Duty Racking.

What are the features & benefits of a Guided Aisle Cantilever Racking system?

- 100% accessibility to individual packs, thus making product retrieval more efficient

- Configuration provides higher density than that of Conventional and Free-Path systems

- Specialist side loading trucks or multi-directional reach trucks are required to operate within reduced aisle widths

- Better space utilisation resulting in increased storage capacity

- The increased costs incurred for specialist trucks can often be offset by the added value to your warehouse and reducing the risk of damage

Racking Variations We Offer

- Single-sided or Double-sided variations

- Top quality durable powder coated finish for internal applications

- Hot dipped Galvanised finish for external applications

- Heavy Duty Arms in standard or bespoke lengths

Stakapal are full members of SEMA (Storage Equipment Manufacturers Association), with our installation and inspection teams fully SARI (SEMA Approved Rack Inspector), and SEIRS (Storage Equipment Installers Registration Scheme) registered.

Read some of our Cantilever Racking-related posts

Stakapal Cantilever Racking is ‘key’ to solving Timber Storage issues

Cantilever Racking Solution When Frank Key (Nottingham) Ltd a large privately owned independent supplier of building and timber supplies, with

Cantilever Racking for Timbmet Distribution Centre

Cantilever Racking is one of Stakapal’s most popular and sought-after racking solutions for timber merchants. Cantilever Racking – Timber Storage

Cantilever Racking: Key Structural Components

Stakapal’s unique Cantilever Racking system was designed with the most robust box structure so that our customers from different sectors could confidently store

Cantilever Racking Systems FAQs

Cantilever racking is designed to store long, bulky items like pipes, timber, and steel bars. It features arms extending from a central column, allowing easy front access for loading and unloading.

Common types of cantilever racking include: conventional racking, free path racking, and guided aisle racking.

It offers easy access, flexibility, and is ideal for items of varying lengths. It can handle heavy loads and is suitable for both indoor and outdoor storage.

Yes, Stakapal’s hot-dipped Galvanised Cantilever Racking for external applications can also be supplied with a canopy roof for additional protection from the elements. Traditionally utilised by Timber and Builders merchants who have a large requirement for storing Carcassing Timber, a canopy roof is frequently requested as part of the installation in yard areas. We work with the customer to find the most cost-effective solution.

Typically made from steel for strength and durability, and it can be galvanised for corrosion resistance, especially for outdoor use.

Our tapered arms are available in a wide range of lengths from 600mm up to 2100mm, depending upon bespoke requirements. Our most common arm lengths are 1220mm and 2100mm which are widely used in the Timber and Panel Products industries. Arm loadings are available from between 500kgs to 2000kgs.