Racking Installation by Stakapal

Home » Racking Installation by Stakapal

Racking Installation - Why choose Stakapal as your Racking Supplier?

At Stakapal, we bring nearly 60 years of expertise in manufacturing high quality racking solutions, making us a trusted name in the industry. Our commitment to innovation and customer satisfaction is what sets us apart from the rest. We offer bespoke racking designs tailored to your specific needs, with all products manufactured in our state-of-the-art UK facility. We also provide our Racking Services such as our installation and inspections, so you do not need to go anywhere else.

Our dedicated in-house team ensures a seamless racking installation process, as full members of SEMA and HSE advocates, we adhere to the highest industry standards. Choose Stakapal for reliable, efficient, and innovative storage solutions.

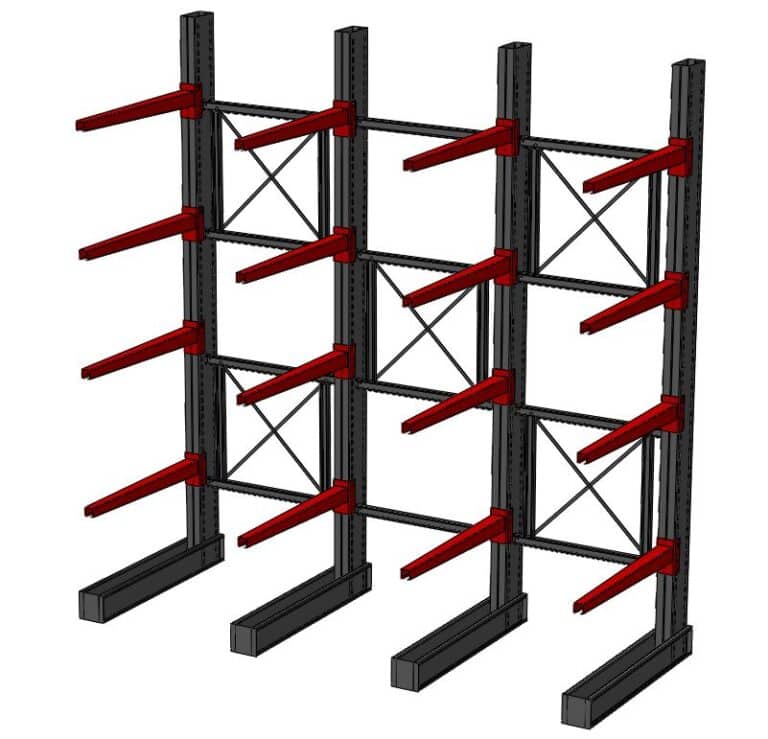

Cantilever & Pallet Racking Installation Experts

Your partner for racking installation, Stakapal have you covered

Complete qualified racking installations from SEIRS registered installers.

The Process:

Step 1: Site Visit

One of our in-house engineers will visit your site to further understand your requirements, needs and space available.

They will measure the area and ask you questions about your handling equipment, stock and loading demands.

We will consider every to maximise your storage space aspect in step 2.

Step 2: Design & Quote

Our projects and design team will work together to design a drawing showing the best racking solution for you.

We work with you every step of the way and provide suggestions (e.g. more efficient handling equipment) so that you really get the most out of your space.

Once your proposed design and quote are complete we will be in touch to walk through it with you.

Step 3: Order

Happy with your design and quote?

Our sales team will help you make your order and answer any questions you may have. Your order be sent to our in-house factory where we will begin manufacturing your bespoke racking solution.

We will provide you with a more precise lead time and schedule your installation period. We also include Load Labels as standard.

Step 4: Manufacture

Every project starts from a steel coil which is transformed into bespoke elements by our manufacturing team of welders, technicians and engineers.

They can also paint your racking to a colour of your choosing, our favourite is Stakapal Red!

Did you know we are the only UK-based manufacturer of both Industrial Cantilever Racking and Industrial Pallet Racking?

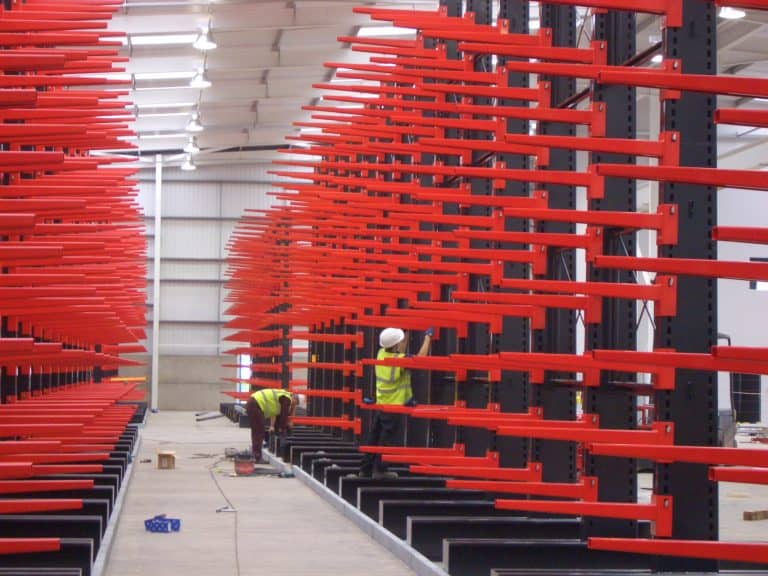

Step 5: Racking Installation

Your racking will arrive before installation day and our teams will explain to you what will happen on the day, alongside what we need from you.

We don’t outsource our installation team, so every member is hired directly by Stakapal, and as such are completely professional and always trained to the highest of standards.

Every member of our installation team is registered through SEIRS (Storage Equipment Installers Registration Scheme).

Success: Happy Customer

That’s it! Your new bespoke racking has been safely installed and ready to load up with your stock.

We take pride in all the projects we undertake and always ensure that you are happy with the finished product and encourage any feedback.

Health and safety is paramount to us and as industry leaders within the racking industry, we also offer annual racking inspections with our in-house SARIs (SEMA Approved Racking Inspectors).

Why Customers Love Stakapal

View Our Product Range

Read some of our Racking Inspection posts

Proper Installation and Relocation of Storage Racking Systems

Risks Compliance Liability Stakapal Conclusion At Stakapal we know the importance

Selecting the Right Racking System for Your Industry

The right racking system is essential for optimising storage and

The Importance of Bespoke Storage Solutions

In this ever-changing world of storage, with new sectors, new

Racking Installation FAQs

Installation involves assembling the frame, securing it to the floor, and adding beams and shelves, following the manufacturer’s instructions and safety standards.

Yes, by ensuring the installation has been put together by a trained and qualified SEIRs member, this will ensure compliance with safety standards and optimal performance, though some systems can be user-installed - which is at the discretion of the individual and is not something we personally advise.

Floors should be level, strong enough to support the load, and free of cracks. Concrete is the most common flooring used.

Installation time varies. A simple setup might take a few hours, while a large, complex system can take several days.

Permitting requirements vary by location. Check with local building authorities to determine if permits are needed.

Racking Inspections FAQs

Racking inspections ensure the structural integrity and safety of the racking system, preventing accidents and ensuring compliance with regulations.

Conduct regular inspections at least once a year, with more frequent checks if the racking is heavily used or if there are known issues. Stakapal offers all its customers the opportunity to schedule an annual SEMA Racking inspection as part of our ongoing support services. These inspections are conducted by our own in-house SARI’s.

Inspections can be done by trained SARI (SEMA Approved Racking Inspector) whom are knowledgeable about racking systems and safety standards.

During a racking inspection, a SARI will look for damaged components, loose bolts, signs of overloading, proper alignment, and signs of wear or corrosion.

Unload the affected area immediately, mark it as out of service, and arrange for repairs or replacements. Do not use the damaged racking until it is properly repaired.