At Stakapal we know the importance of proper installation and relocation of racking systems. As full SEMA (Storage Equipment Manufacturers Association) members our installation teams are SEIRS (Storage Equipment Installers Registration Scheme) registered to ensure safety, compliance and operational efficiency in your warehouses, yards and retail facilities.

Understanding the importance of proper installation and relocation of racking systems is key to reducing the risks caused by improper practices and the detrimental effect they could have on a business.

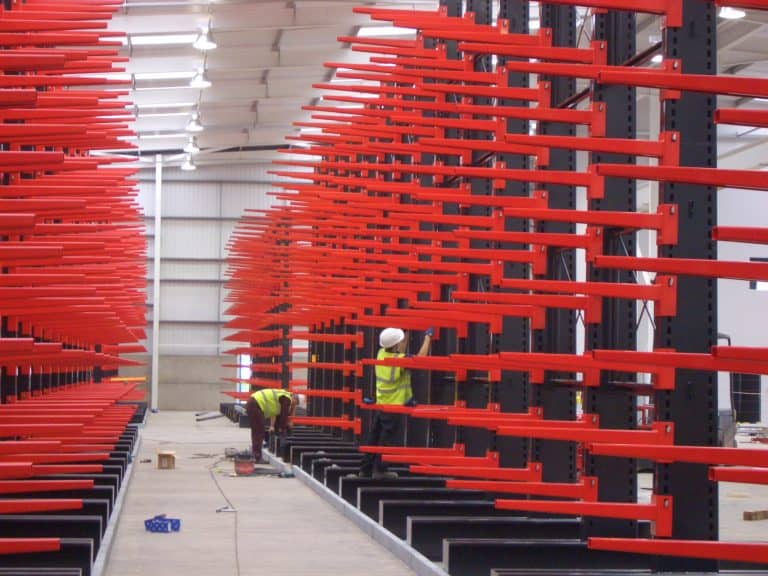

Complex Racking Systems Require Expertise

Racking systems are more than just shelves; they are complex structures with upright frames, beams, braces, and decking. Installing or relocating these systems requires specialised knowledge and skills. Professionals who understand the design and assembly process can ensure the system’s structural integrity and safety.

Safety Risks of Incorrect Installation

Installing racking systems incorrectly poses significant safety risks. Structural instability can lead to accidents, injuries, and damage to inventory. Following manufacturer guidelines and industry standards during installation is crucial to maintaining a safe working environment.

Be aware when buying racking second hand most reputable racking manufacturers will conduct a site visit to help you choose the best system for your space.

Compliance with Safety Regulations

Racking systems are subject to various safety regulations and building codes, which can vary by location. Adhering to these regulations is essential to avoid fines and legal liabilities. Proper installation and relocation, including updating load notices and capacity labels, help ensure compliance with these standards.

Not sure if your racking is compliant?

Liability Considerations

If accidents or injuries result from racking installed incorrectly the responsible parties could face legal liabilities. This includes facility owners, operators, contractors, or anyone else involved in the installation or relocation. Failing to follow safety standards and maintain accurate load notices can worsen legal consequences and harm a company’s reputation.

Importance of Professional Assistance

Given the complexity and risks, it is crucial to enlist qualified professionals. SEIRS is the industry standard qualification – for racking installation and relocation projects. The scheme ensures installers have the necessary knowledge to do the job safely and efficiently.

Ask your installer for their SEIRS ID (or SEIRS CSCS card), alternatively, you can contact SEMA directly to check your installer is qualified.

Stakapal: SEMA Approved Racking Installation

As a full member of SEMA, Stakapal is well-equipped to ensure proper installation and relocation of storage racking systems. Here’s how we contribute:

Adherence to Standards

Stakapal follows industry standards for designing, manufacturing, installing and inspecting racking systems, ensuring high quality and safety throughout.

Installation Expertise and Training

Stakapal, provide their in-house installation teams with full SEMA training and regular refreshers on proper techniques, load capacities, and safety considerations so they properly conduct themselves when on site.

Consultation and Installation Support

Stakapal provides a concept-to-completion service, meaning our teams work with you every step of the way from planning, design, and implementation, ensuring layout optimisation and regulation compliance.

Stakapal also offers the opportunity to schedule an annual SEMA Approved Racking Inspection with our in-house SARI’s (SEMA Approved Racking Inspectors) as part of our ongoing support services – so why go anywhere else?

Product Innovation

Stakapal develops bespoke, innovative racking solutions that are tailored to your needs and meet your specific warehouse specifications to help exceed efficiency goals.

Advocacy and Awareness

Stakapal prioritises safety, compliance, and operational efficiency by following best practices and training staff to the highest standard so that businesses can mitigate risks, and protect employees and assets whilst maintaining productivity.

Stakapal, with their expertise and commitment as SEMA members, plays a vital role in the proper installation and relocation of racking systems.

Conclusion

Proper installation and relocation of storage racking systems are critical for safety, compliance, and operational efficiency in storage environments. By prioritising correct practices and seeking professional assistance, businesses can mitigate risks, protect employees and assets, and maintain productivity. Stakapal, with their expertise and commitment as SEMA members, plays a vital role in ensuring safe, compliant, and efficient storage solutions.