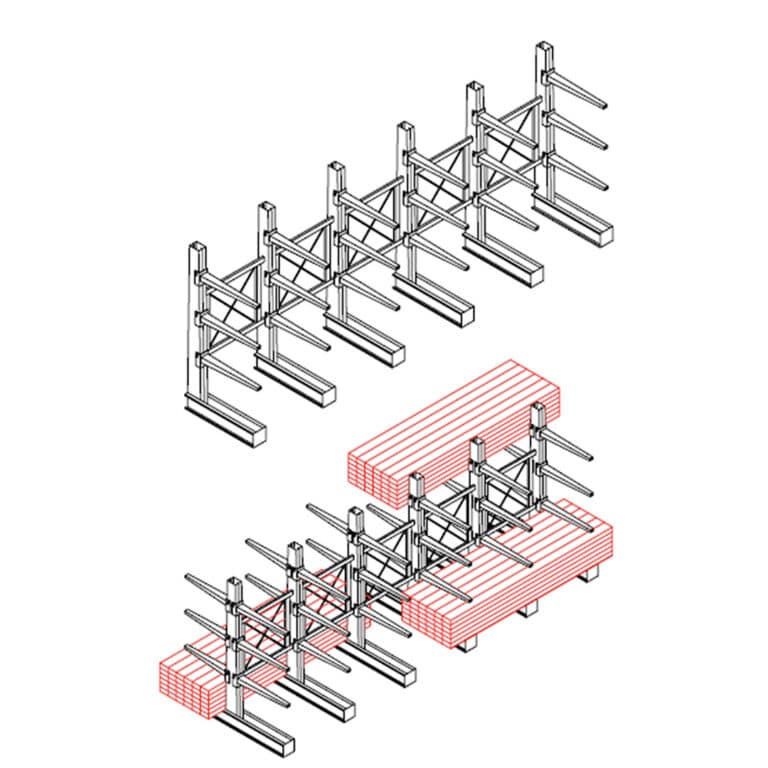

Single Sided Cantilever Racking

Compared to double sided cantilever racking, single sided cantilever racking is a type of industrial storage system designed as solution for storing long and bulky items such as pipes, timber, panel products, steel bars, extrusions, and more. It is constructed with vertical steel columns with horizontal arms that extend out from the columns to support and store items. It’s a simple yet adjustable and effective storage option.

The term ‘single-sided’ means that the racking system only has arms on one side, allowing it to be placed against a wall or other structure. The design maximises available storage space while minimising the amount of floor space needed for the system.

Cantilever racking is ideal for businesses storing long and heavy items, with a range of arm lengths and loading capacities available whilst offering easy access to products. It is commonly used in warehouses, manufacturing facilities, timber sheds and yards.

Space required for Single Sided Cantilever Racking

The overall area required for any single sided cantilever racking installation varies depending on the specific needs of the user and the size of the items being stored. The height, depth and length of the racking system can all be customised to meet each individual customer’s storage needs.

Stakapal offers a bespoke service to every customer from the initial site survey through to design, manufacture, and installation. Our in-house design and projects team work with you every step of the way, advising at each stage. All racking systems at Stakapal are designed to the SEMA codes of practice and installed by one of our SEIRS registered in-house installation teams.

We offer a free site-racking survey service and guide you through the complete process from start to finish.

After Installation

Single sided cantilever racking is a versatile system that can be adjusted to meet changing stock profiles. Stakapal’s arms have a wedge pin system that makes arm relocation quick and easy whilst relevant loading capacity is adhered to.

Stakapal also offer annual SARI racking inspections for all single sided cantilever racking systems that were originally designed and installed by ourselves. These can be booked directly with Stakapal and will be carried out by one of our in-house Inspectors. Following the SEMA traffic light system, we record categories that are Green, Amber or Red Risk. A full written report will be then issued, along with our proposals for any action that needs to be implemented.

Stakapal are full members of SEMA (Storage Equipment Manufacturers Association), with our installation and inspection teams fully SARI (SEMA Approved Rack Inspector), and SEIRS (Storage Equipment Installers Registration Scheme) registered.

View Our Product Range

Read some of our Cantilever Racking posts

Cantilever Racking Inspections: Why are they necessary?

It is usually an Environmental Health Officer (EHO) from the local council, or a Health and Safety Executive Inspector that demands that a company obtains a racking inspection of its cantilever racking by a ‘technically competent person’.